-

-

Unique Process

-

-

-

-

-

Business college

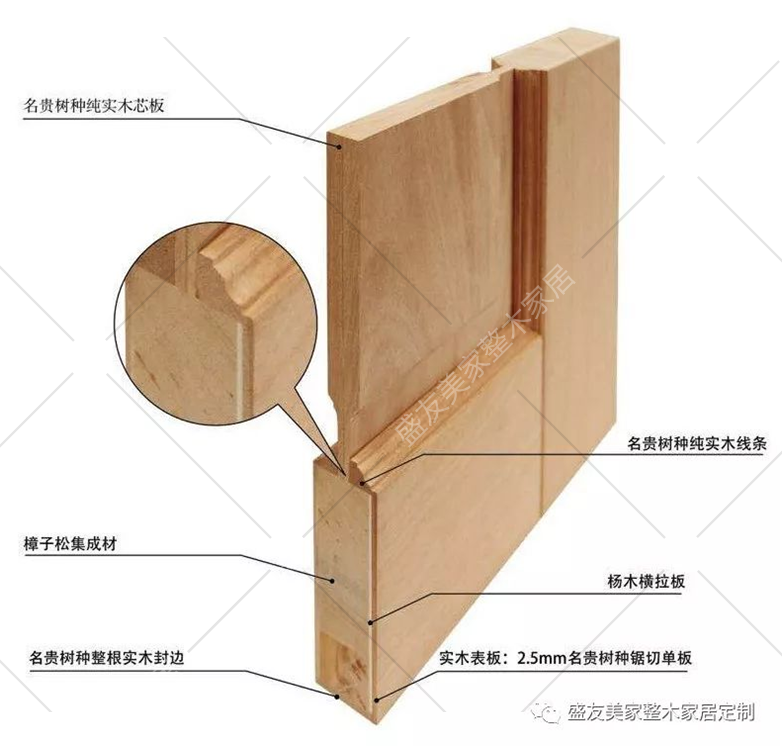

THREE LAYERS OF SOLID WOOD

// Three - layer solid wood, deep transverse pull is not easy to crack deformation //

Sandwich is a wood processing method of Shengyou solid wood technology products. By combining solid wood component products with different textures (natural veneer or sawn veneer) in a criss-cross vertical way, it can produce a deep transverse pull effect, which can reduce the probability of wood deformation and cracking to a large extent, and make the solid wood products more stable. But because of its complex processing process, and then increase a lot of labor costs; Because of the large material loss in the process of processing, it increases a lot of material costs. Compared with the single board log process on the market, this process has large loss, high material cost, many processes, and large labor costs. Many factories are faced with such large costs and expenses. But the wooden products processed by this process have more stable performance and superior quality.

Taking Shengyou real wood doors as an example, the "sandwich" process is reflected in door core plate, door door (including dock and door spike) and door cover plate, as follows.

1.40mm thick wood door product technology

2.45mm thick wood door product process

3. Solid wood door frame (door + dock + door spike) product technology

4. Solid wood door cover plate product technology

About Shengyou unique "sandwich" product process description

1. Sandwich log core board: Solid wood door core board, three layers of FAS grade solid wood wood, according to the wood texture crisscrossing, composite together, make the door core board more stable, not easy to crack.

2. Five-layer solid wood frame: Door frame, including door, dock and door lift, is made of five layers of solid wood, which is staggered and combined together. As the door frame plays a load-bearing role, the base material is 100% filled with camphor pine (SPF base material) after "defatting drying", which makes the heavy solid wood door more stable and not easy to deform. The frame surface is made of 2.5mm thick FAS highest grade solid wood veneer, which ensures the stability of solid wood products and makes the products have a better appearance.

Remarks: Sylphor pine (SPF base material) is more stable after "degreasing drying".

3. Shengyou will extend this "sandwich" process from solid wood doors to wallboard, wardrobe doors and other house solid wood customized products, so that Shengyou solid wood customized products process succession, quality as always, stable and reliable quality.

Dalian Shengyou Meijia Home Co., LTD

ADD: Shli Industrial Park, Jinzhou District, Dalian City, Liaoning Province

TEL:156-4087-2497

URL:en.shengyoumeijia.com